Ever wondered how industries safely handle strong chemicals or ultra-clean fluids?

In many places, like chemical plants, food factories, or labs, fluids flow through pipes all day. But not just any valve can manage them. Some fluids are highly corrosive, while others must stay very pure.

So, how do engineers make sure these fluids move without causing damage or contamination?

The answer often lies in a special type of valve called the diaphragm valve.

What is a Diaphragm Valve?

A diaphragm valve is a type of control valve that uses a flexible diaphragm to control the flow of liquids. The diaphragm presses down to block flow and lifts to allow it.

Since the diaphragm forms a barrier between the fluid and other parts of the valve, it helps prevent leaks and keeps the system clean.

This simple mechanism makes diaphragm valves very useful where hygiene or chemical resistance is important.

Where Are They Used?

Diaphragm valves are used in many areas. In chemical processing, they can handle strong acids and bases.

In the pharmaceutical and food industries, they keep fluids pure without risk of contamination.

Even in water treatment, they play a big part. They are trusted wherever clean and reliable flow is needed.

Why Diaphragm Valves Work So Well in Tough Conditions

Diaphragm valves are built to handle tough environments.

Here’s why they stand out:

1. No Leak Paths

The way a diaphragm valve is designed keeps the fluid separate from the moving parts. This means there’s no room for leaks. It’s very safe for handling harsh chemicals or high-purity fluids.

2. Easy to Clean

Since the fluid only touches the diaphragm and the valve body, cleaning is much easier. That’s a big plus in the food and pharma industries, where hygiene is everything.

3. Suitable for Corrosive Fluids

Some fluids can damage regular valves. Diaphragm valves, when made from the right materials, resist this damage and keep working well. That’s why they’re often chosen for chemical applications.

4. Smooth Flow Control

These valves don’t just open and close. They can also help control how much fluid flows through, giving better handling of the system overall.

Material Choices That Make a Difference

The material of the valve body and diaphragm is important. Options like PVDF, PTFE, and EPDM are often used for their strength and resistance.

The right match between material and fluid ensures the valve will last longer and perform better.

How They Compare with Other Valves

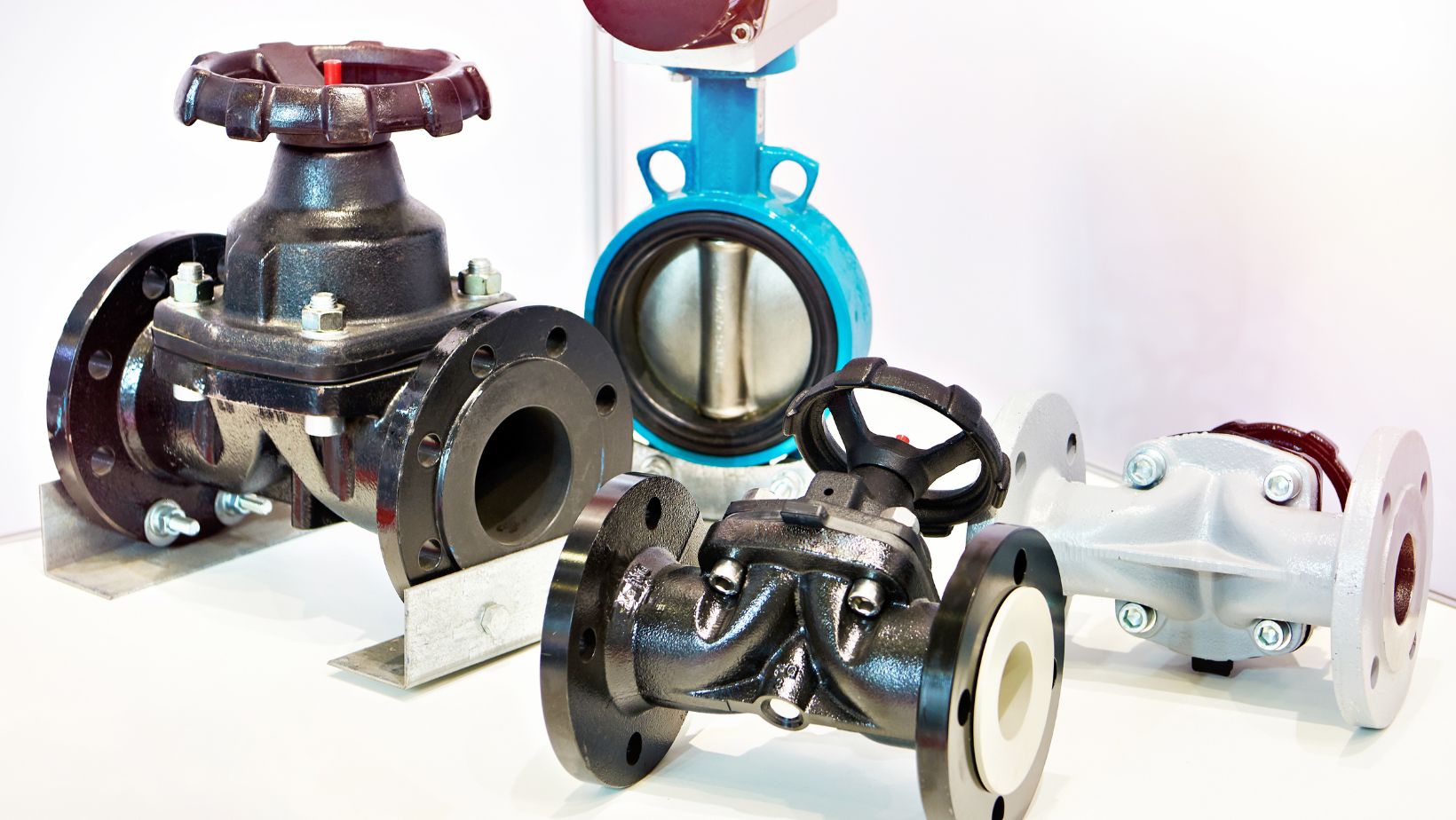

Other types of valves, like plug valves, gate valves, or even ball valves, are also used in industries. But diaphragm valves bring something extra, especially for fluids that are either dangerous or need to stay extremely clean.

In many settings, engineers may also rely on other valve types for different flow conditions.

For instance, in low-pressure systems where frequent shut-offs are needed, many turn to PVC Ball Valves. These are easy to operate and quite common in everyday fluid handling tasks.

Supportive Role of Other Valve Types in the System

Even though diaphragm valves handle some of the most critical jobs, they don’t work alone. Other valve types are often used in the same systems.

One popular example is the butterfly valve. These valves are useful for managing larger volumes of fluid and are simple to control with minimal effort.

Benefits of High-Purity Systems

High-purity systems are found in industries like biotech, electronics, and pharmaceuticals. These systems must avoid any contamination, no matter how small.

Diaphragm valves are perfect here because:

- They have fewer parts that touch the fluid

- They allow clean-in-place processes without removing the valve

- Their design makes it harder for bacteria or particles to stick

Long-Term Use and Maintenance

Diaphragm valves are not only reliable during use, but also simple when it comes to upkeep.

Since there are fewer parts and less contact with the fluid, the chance of wear and tear is low.

Even if the diaphragm needs to be replaced, it can often be done without removing the entire valve.

Common Applications Across Different Industries

These valves are not just used in one place. You’ll find them in:

- Chemical production plants

- Laboratories

- Food processing units

- Water purification systems

- Power plants

- Beverage factories

Can Diaphragm Valves Handle High Pressure?

They are best suited for low to medium pressure systems. If a system needs to handle very high pressure, other valve types might be more suitable.

But for corrosive or clean applications with regular pressure needs, diaphragm valves work beautifully.

Automation Possibilities

Diaphragm valves are also easy to automate. They can be connected with actuators and sensors to monitor and control flow without manual effort. To maintain tight process control in corrosive and high‑purity loops, pairing diaphragm valves with precise inline metering is common. Among the most hygienic, drift‑resistant options are Coriolis mass flow meters, which directly measure mass flow and density without moving parts, tolerate clean‑in‑place routines, and perform reliably across changing viscosities. Integrated with valve actuators and PLCs, they enable closed‑loop dosing, batching, and CIP chemical control while minimizing shear, pressure drop, and contamination risk.

This is very useful in modern industrial systems where automatic control is expected.

Installation Tips to Get the Best Out of Diaphragm Valves

For the valve to work properly, installation needs to be done correctly. Here are a few easy points to keep in mind:

- Always use the valve material suitable for the fluid being handled

- Ensure that the valve is mounted in the right direction

- Try not to overtighten connections, especially in plastic valve models

- Make sure the diaphragm is replaced at regular intervals for systems in constant use

Energy Saving and Environmental Benefits

Diaphragm valves also help reduce waste and energy loss. Their smooth operation ensures that fluids flow in the right direction without sudden pressure drops.

This is good for energy bills and also reduces the risk of fluid loss or leakage. Their long lifespan means fewer replacements and less material waste over time.

Final Words

Diaphragm valves quietly play a very important role in keeping sensitive fluids safe and systems clean. Their smart design, material strength, and ease of maintenance make them a smart choice for industries working with either dangerous chemicals or pure solutions. By using the right type of valves in the right places, like adding butterfly and ball valves where needed, industries can run things more safely, smoothly, and efficiently.